The lathe is a machine that performs different functions, such as drilling, boring, knurling, etc., on a working piece for making a properly defined product. The basic difference between a capstan and a current lathe machine is that a capstan lathe is high speed due to light construction, and a current lathe is a slow speed that is used for rigid designs. These two are the main types of lathe machines that are used for performing mass production. Each comes with its own features and benefits. Here we will cover details for finding their differences.

What is a turret lathe?

- The current lathe is a metalworking lathe that is used for the manufacture of repetitive, identical parts that are interchangeable.

- It is a type of older lathe machine, but the difference is the turret, which is an indexable toolholder that helps to perform different cutting operations.

- Each performs with a different cutting tool in fast succession; there is no need of an operator for performing operations or for controlling the toolpath.

- •The turret lathe machine is an advanced type of engine lathe machine. This machine is used for bulk production.

- It is a heavy-duty machine and used for larger-sized working components.

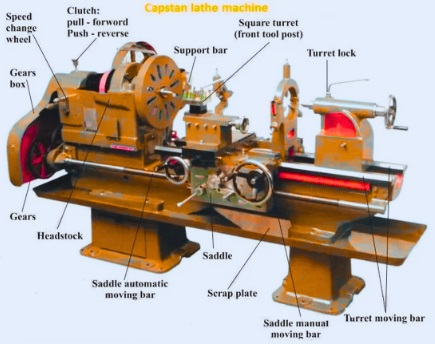

What is a capstan lathe?

- A capstan lathe is an advanced type of engine lathe and center lathe where a tailstock is used for a hexagonal turret tool head.

- It was first used in 1860, and it was made at that time to fulfill the requirements since a single tool holder exists in the center lathe and one tool is configured on the tailstock.

- That was a time-taking process and needed to change tools for varying functions on working components.

- Center lathe is not good to use for bulk productions

- For handling this limitation, a capstan lathe was made, and a capstan lathe is an advanced type of center lathe. That comes with 6 different types.

- • The turret tool rotated to get the required tool for the functions. It is part of bulk production for making larger products with high accuracy in a short time.

- It is basically a semi-automatic machine that performs machining processes like drilling, facing, thread cutting, etc.

How Does a Capstan Lathe Work?

- • The capstan lathe comes with 6 tools in a hexagonal tool holder. The first one is a working component that is converted into a different shape based on the requirement put in the chuck.

- • A chuck is a 3-jaw or 4-jaw chuck; the working component moves with the chuck that is connected with the spindle.

- hexagonal tool head comes with 6 different points for handling 6 tools.

- If the working component configured with the chuck rotates, the hexagonal tool heat moves in the direction of the working component with the saddle.

- • The hexagonal tool head rotates, and the turning tool needed for machining is directed to working components.

- When the required tool is toward the working component, the tool makes a connection with the working component through ram advancements and performs the required functions.

Features Capstan Lathe Machines

- Automation and quick tool variations provide high production rates and reduce time for manufacturing.

- The precise control of the capstan lathe machine provides constant and error-free matching and reworking.

- Effective machining processes of these machines also reduce labor cost and downtime.

- Capstan lathes easily handle different materials and machine functions and give flexibility for manufacturing.

- The machine comes with quality components and provides constant machining that fulfills the industry standards and our expectations.

Turret Lathe Working

- • The turret lathe comes with current tool heat that is configured on the saddle. As compared to a capstan lathe, feed is provided with a moving saddle unit that helps the current tool heat to move on the complete bed in the longitudinal direction. That helps the machine to handle longer working components.

- • The turret lathe also comes with multiple tools, as the capstan lathe does. That helps to perform different functions at the same time without requiring a tool.

- The features help to provide high efficiency and productivity for machines.

Difference Between Capstan and Turret Lathe Machines

Capstan Lathe Machine

- This machine is light duty, and its tool head is configured in ram, and the ram is connected to the saddle.

- For providing feed, machine ram motion is needed.

- It is used for small working components since the ram has limited motion.

- Its light weight makes it a high-speed machine.

- Heavy cuts are not provided through this machine since it is of a non-rigid design.

- It is a horizontal lathe.

- • The machine turret head does not move crosswise, and it is easy to move the turret head since it moves over the ram.

- For holding working components, collect used ones, and it can perform machining functions up to 60 mm in diameter.

- It has low lengthwise motion of the machine. The turret head moves manually.

- Limited feed and depth of cut it has that causes lower matching than a turret lathe.

- It is a lightweight machine and used for mass production.

Turret Lathe Machine

- It is a heavy-duty machine, and its tool head is on a saddle.

- It needed feed saddle motion.

- It is used for larger working components since the ram motion is limited.

- It is a slow machine; it does not provide a larger cut due to its rigid design.

- It works in horizontal and vertical operations, and the current head moves crosswise.

- It is not easy to move the current head over with the saddle.

- For holding the working component, it has a jaw chuck, and the machine performs working on the component at about 60 mm.

- The turret head does not move manually, and matching provides more feed and a deep cut.

- It is a high-weight design machine, and the current lathe has features for moving current at 90 degrees to the lathe axis.

- It is good to use for bulk production.

Applications of Capstan Lathe

- Capstan lathe machines are used for making accurate and precise components for engines, steering systems, and other parts of vehicles.

- In the aviation industry this machine is also used for making landing gear parts, aircraft engine parts, and hydraulic fittings.

- Capstan lathes are important for making complicated components of electronic devices like housings, connections, and PCB board components.

- It is also used for making different medical devices such as implants, surgical tools, and diagnostic equipment.

- It also makes nuts and bolts and other instruments like screws and other engineering tools.

Read also: What Is Locknut? Features, Types, and Application

Types of Turret Lathes

Vertical Turret Lathe

- Vertical lathes, also called vertical boring mills, are configured with working components at 90 degrees, or vertically. A vertical turret lathe is like a huge potter’s wheel since it has a horizontal rotating table.

- The vertical boring mill comes with a turret that is good for larger, heavy, and short working components.

- It can move sideways, and the turret also moves up and down. The vertical turret lathe has features to hold 14 different tools.

Automatic Turret Lathe

- From the 1870s to 1890, automated turret lathe machines were made. These machines easily apply different part-cutting cycles without any person working.

- So it reduces the working of the operator that was required for the manual turret lathe, and it increases productivity. These machines operated with cams for automatic sliding and indexing of the turret and controlling the chuck.

- Small- to medium-sized automatic turret lathes are screw machines or automatic screw machines, and larger machines are called “automatic chucking lathes” or “automatic chuckers.”

Computer Numerical Control (CNC) Turret Lathe

- In 1945 digital computers made that become part of business and industry. The use of computer-based automation tools through numerical control and computer numerical control was common but with manual and mechanically automated machines.

- • A numerically controlled turret provides automated tools used on the turret. CNC lathes operate in any direction, horizontal or vertical, and come with 6 separate tools on one or more turrets. These machines operated 2 axes for one turret.

Summary

The basic difference between a capstan and a turret lathe machine is their design, working functions, and applications. The capstan lathe is low in height and good to use for small operations.

The turret lathe is a high-duty machine and made for larger and intensive operations.

The use of capstan and turret lathe machines is based on operation demand. For high speed and efficiency with small components, the capstan lathe machine is used. For larger working components and heavy cuts, a turret lathe is best to use.

FAQs

What Is the Difference Between a Turret Lathe and a Regular Lathe?

- The conventional lathe holds one cutting tool at one time. That affects production since we perform task repetitions. The turret lathe is an advanced type of conventional lathe. That can handle different tools over the turret tool heat for providing high production that avoids many operations in just one session.

What is the difference between a capstan and a turret lathe?

- Capstan lathe machine operation is high speed since it has a lightweight design, and the turret lathe working machine is slow speed and has a heavy design.

What are the limitations of a turret lathe?

- • A turret lathe required a skilled person and high-cost tools and programming. Turret lathes are not as good to use for small parts creation as traditional lathes.

What are the uses of a capstan lathe?

- Capstan lathe machines are best to use for light-duty operations. The turret head is on a ram that provides easy sliding motion. We can perform many operations with the capstan lathe machine, such as turning, drilling, grooving, etc.

What are the features of a capstan?

- Capstan winches come with a vertical drum that is used for pulling in a horizontal direction. Its main features are space saving, easy to use, and leases line from drum at different angles.

- Its limitation is that it needs high costs for installation and lift for weight at high speeds.

What is the purpose of the turret on the lathe?

- • The turret lathe has features of different cutting tools at the same time. So there’s no need to swap cutting tools. The turret lathe switch is for accurate cutting tools and provides a high-speed and effective manufacturing process.

What is turret lathe classification?

- There are different types of turret lathes; turret lathes are defined by different operations. Common turret lathes are semi-automatic, vertical, and flat.

What are the different types of lathes?

- Speed Lathe Machine.

- Center Lathe or Engine Lathe Machine..

- Automatic Lathe Machine.

- Special Purpose Lathe Machine.

- Turret Lathe Machine.

- Toolroom Lathe Machine.

- Bench Lathe Machine

- CNC Lathe Machine.

What are the 7 lathe operations?

- Cutting

- Drilling.

- Sanding.

- Knurling.

- Deformation.

- Turning.

- Facing.