A car comes with different parts, like the wheels, which are also a main part of the car that help the car to move. The wheel looks like just a normal component that supports the car’s weight. But a car wheel comes with some further parts, and each has its importance. In this post, we will cover the details for different parts of the wheel and their diagram.

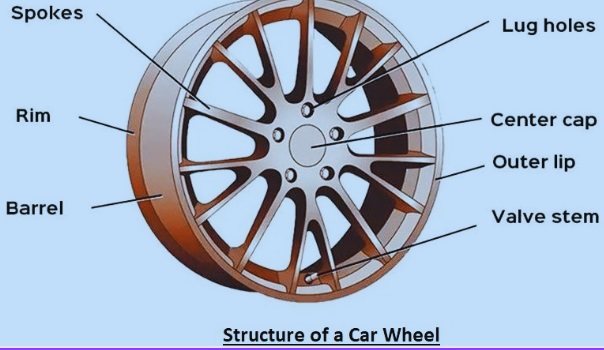

Structure of a Car Wheel

- The car wheel is made to provide support to the vehicle and also helps to ensure a smooth motion.

- If you do not have a car wheel, your vehicle will not move. It also comes with different parts that have stability and features that provide a strong grip and a durable nature.

- The core car wheel’s main parts are the rim, hub, tire, and spokes, and each performs certain work.

- The rim of the car and tires are part of the wheels, which sometimes confuse. Rim holds the tire in a certain position, and the tire is rubber that covers the rim and provides grip.

- Modern car wheels operate in combination with the automotive steering system and are interfaced with car suspension parts.

Basic Parts of a Car Wheel

Tire

- The tire is an important component of the wheel and also helps to provide a good ride. Tires keep our driving smooth and comfortable. The tire used must have such features to move in different conditions, like icy, snowy, or wet conditions, which helps to have a strong grip in adverse conditions.

Wheel Bearings

- Moving wheels and static vehicles are connected through wheel bearings that help to make a frictionless connection.

- Anti-friction bearings are part of the 4 wheels of the car. Anti-friction bearings come with inner, rolling, and external race components.

- Bearing cages make a difference for rolling components. The seal helps to lubricate and avoids dirt and water.

Rim

- The rim is like a skeleton, and the tire is like the skin of the wheel assembly. Rims and tires are configured with each other since rims provide support and help fill air in the tire. Rims are made of steel and aluminum.

- They come with plastic bits that are like caps configured; they are like burnished chrome. Rims come with different styles based on the model.

- For trucks, strong rings are used for carrying heavy weight. The style is also important for good design.

Wheel Hub

- The wheel hub makes a connection with the rim and hub. Brake pads, calipers, and rotors are part of the wheel hub. It is configured with an axle and helps the car move and stop. The wheel hub is connected with tires and 5 bolts through lug nuts configured from the hub center.

Valve Stem

- The car tire valve is an important part of the wheels that helps car tires inflate and deflate. Air needed for fill chambers is added through this part and released if needed.

- If it is closed, it retains air inside and avoids releasing. It is an important part that maintains tire pressure.

- Tire valves’ main feature is that. It has a deflating and inflating design and does not leak.

- It checks the inner pressure and replaces it with an inner wall.

- It needed to be a uniform design and stable pressure in the tube.

Outer Lip

- This part of the wheel lies in front of the spoke. Dish work for a larger area. A wheel is defined as a deep dish wheel if the spokes are on the inner side compared to the external edge.

- It is performed through vanity since it is susceptible to damage.

Barrel

- The barrel is the external part and helps the structure of the tire to form. The barrel also has some external parts that come with a circular rim that moves the inner side axis in the horizontal plane with a center that is a drop center.

- A wheel that has a drop center close to the face of the wheel is called a front mount wheel, and a drop center close to the back face of the wheel is called a reverse mount wheel.

- The barrel edges are moved outward for making flanges. These flanges are used for avoiding the tire leaving the wheel.

Wheel Fasteners

- Wheel fasteners are part of each car and other vehicles. For tire design, the connection of the rim with the hub is important. Threaded bolts, connected into the hub or flange, are common wheel studs.

Valve System

- The valve system helps to inflate and deflate tires. The valve system of wheels is connected to a tire pressure monitoring system that helps to check pressure at any time.

Center Cap

- Vehicle wheel rims and tires are protected from dust and sunlight through the use of wheel center covers.

- They are important, especially when parking in a public area. Spokes are in the center of the wheel, and the middle cap exists there. Central cap removed on different vehicle, but some wheel rims do not have a removable center cap.

Center Bore

- The machined hole is in the center of the wheel, helping the wheel to lie in the center of the vehicle. Proper centricity of the wheel minimizes vibration. It is normally the space that comes with operational space that moves towards the axle and is compatible with the weight of the vehicle.

- It is not easy to fit wheels if the hub collar’s diameter is larger compared to the center bore.

Mounting Humps

- Small ridges lie over the bead rest, helping to avoid tire beads slipping and controlling the bead at their certain position.

Manufacturing Methods for Car Wheels

There are three main types of methods used for wheel manufacturing that are explained here.

Forging

- Forging is a high-pressure process where solid metal billets are converted into different wheel shapes. This technique makes dense and strong metallic designs with high quality and resistance factors.

- This process makes the wheel low weight and strong design as compared to the cast wheel. They are a good option for high-performance vehicles.

- Forging is used for making complete designs of sophisticated cars. Normally it is used for making central components of wheels, such as inner rims and wheel centers.

Casting

- • The casting process involved heating metals to a molten state and pouring them into a premade mold cavity for making the design of the wheel. It is a low-cost process and is also used for the mass production of complicated components such as industries and aftermarket wheels.

- Cast wheels have microscopic air pockets that affect quality. So cast wheels are not used for passenger cars and not used for high-performance cars.

Flow Forming

- Flow forming is a hybrid technique that is a combination of casting and forging methods. partially cast wheel gets heated and spun, and rollers apply pressures for materials compression and stretch and make a strong, lightweight design.

- This process refines the external part of the wheel and provides a low-cost option for good performance.

- Flow-formed wheels have good weight features, strength, and low-cost options.

Materials for Making Car Wheels

Aluminum

- Aluminum is a commonly used material for car wheels. It is low weight, resistant to corrosion, and also has a good strength-to-weight ratio. Metal is also good for casting and forging and helps to use for different types of wheels.

Steel

- Steel also has good mechanical features but has a high weight and low-cost option. It has good strength to work in rough conditions like off-road driving and low weather conditions.

- As compared to aluminum, steel wheels are pressed and welded with each other as compared to forged. They are used for heavy-duty vehicles and commercial applications.

Magnesium

- Magnesium-made wheels, also called mag wheels, are low weight compared to aluminum and steel. But low-weight features help to increase their working features and dissipate heat.

- These wheels are part of racing and high-end sports cars due to low-weight features.

- Magnesium is high cost and also has a corrosion effect and needed protective coatings.

Carbon Fiber

- Wheels made with carbon fibers come with a good strength-to-weight ratio, and they are a low-cost option. They provide good acceleration, a braking system, and also high fuel efficiency with durability features.

- They are a high-cost option, so they are used for luxury vehicles. Carbon fiber wheels need proper handling since they are affected from different conditions.

FAQS

What are the different parts of a car wheel?

- The main parts of wheel are listed here and each has is own functions

| S.No. | Component |

| 1 | Wheel Rim |

| 2 | Tire |

| 3 | Valve Stem |

| 4 |

Hubcap / Wheel Cover

|

| 5 | Center Cap |

| 6 | Lug Nuts |

| 7 | Wheel Studs |

| 8 | Wheel Spacers |

| 9 | Wheel Bearings |

| 10 | Wheel Seal |

| 11 | Wheel Bolts |

| 12 | Wheel Locks |

| 13 | TPMS Sensor |

| 14 | Rim Flange |

| 15 | Bead |

| 16 |

Wheel Balancing Weights

|

| 17 |

Wheel Valve Cap

|

| 18 | Dust Cap |

How should we inspect and maintain in-car wheels?

- There is a need to inspect and schedule car wheel maintenance after 6 months of route car service. During inspection, check tire wear, lug nut tightness, and wheel conditions.

Can we customize car wheels for improved performance?

- Yes, for customization of car wheels, certain materials, finishes, and designs are needed to increase performance and reduce weight with a good look.

What component holds a wheel on a car?

- Wheel studs are threaded fasteners that hold on wheels for different vehicles. They are configured directly to the vehicle hub, normally through the brake drum. Lug nuts are connected on the wheel stud for wheel securing.

What are the 4-wheel drive parts called?

- These components are the clutch, gearbox, propeller shaft, differential, and drive shaft. The driveline features help the engine to operate also if the vehicle is static.