Plug valve, known as a quarter-turn rotary motion valve that employs a cylindrical plug for controlling flow. A disk is a plug-like design that provides a path for fluid flow. The path is in line to flow in an open condition. When plugged in a vertical direction from open conditions, the solid component of the plug stops fluid flow.

This valve is part of high-pressure temperature applications, where we will cover details for plug valves and related functions. So let’s get started. What is a plug valve?

What are plug valves?

- A plug valve is a mechanical component that is used for controlling fluid flow and gases in a piping system.

- It is part of the quarter-turn valve family, so it can be completely opened or closed through a 90-degree rotation of the actuator.

- Its main features are tapered plugs that provide rotation in the body of the valve for controlling flow.

- The plug comes with a hole or path in the middle that provides fluid movement through proper configuration with inlet and outlet valve ports.

- With the rotation of the plug, the path is partially or completely restricted, through which the control flow

- Its simple design provides smooth and reliable working. Its design is round-shaped, having a port on each side that provides an inlet and outlet path for flow.

- Plug strongly connected in the body and move to control flow. For a strong seal if the valve is closed, the plug uses elastomeric or metal seals of the plug and the connection of the valve body.

- This sealing controls leakage and provides strong off conditions when the valve is in a closed condition.

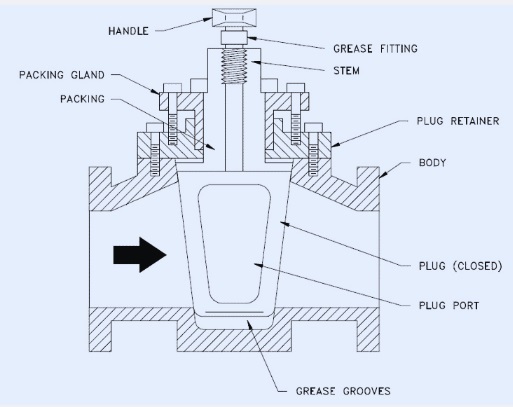

Plug valve structure

There are different parts on the plug valve that exist and are used for providing different functions. The main parts and structure of a plug valve are defined as

Body

- • The valve body is cylindrical in shape, and different materials such as iron or alloy steel are used to make the valve.

Plug

- plug is used for opening and stopping the path of fluid. It is tapered in shape and comes with a hole in the middle.

Stem

- • The stem is used for making the connection of the plug with the actuator.

Bonnet:

- • The bonnet basically covers the valve body and provides leakage proofing at the upper part. It is connected with the body through bolts and screwed at the required point.

Actuator

- The main working of the actuator is to control the movement of the stem, which causes plug rotation. Plug valve actuators come with manual, pneumatic, or hydraulic.

Different Types of Plug Valves

Lubricated Plug Valve

- Lubricated plug valve: a commonly used plug valve since it has good sealing features. It is a cylindrical plug coated with lubricant, like grease, that controls friction and gives uniform operations.

- Lubrication is like a bridge between the valve body and plug that minimizes the effect of wear and gives a strong seal, also for high-pressure conditions.

- lubricated plug valve used in wastewater treatment, oil, and gas industries

Non-Lubricated Plug Valve

- non-lubricated plug valve operated without using lubrication. but uses some advanced materials and a self-lubricating system to control friction and provide a sealing process.

- This valve is used where lubricants cause fluid contamination and improper reactions.

- non-lubricant plug valve part of industries like clean energy and the food and beverage industry

Eccentric Plug Valve

- Eccentric plug valves come with certain design features in which the plug is offset through the center of the valve body. that helps plug to disengage through the flow path for open conditions, reducing wear and also controlling the torque used for the function.

- Eccentric plug valves also have good throttling features and are used where accurate flow control is needed, for example, in chemical processing, power generation, and water distribution systems.

Expanding Plug Valve

- This plug valve provides a strong shutoff by using a plug that has a radial design when moved in the closed state. This expansion provides a strong sealing area over the valve body and controls leakage.

- This valve is used for high-pressure and high-temperature conditions, like steam systems, for providing strong leak-proof features.

Plug valve working

Plug valves provide easy working according to the rotational motion of the plug that controls fluid flow.

Open condition

- When the stem moves for valve opening, the plug’s hollow area is configured for fluid flow. Fluid moves through the valve unobstructed.

open to closed positions

- When the plug moves from open to closed or closed to open conditions, the hollow part of the plug obstructs, restricting, and throttling the flow.

Closed position:

- For closed conditions, the solid component of the plug stops the flow path, controlling fluid flow in the valve.

L-port and T-port plug valve working

L-PORT and T-PORT plug valves come with certain workings according to the plug port design.

L-port plug valve

- An L-shaped flow path exists for the L-port valve. When the plug moves at 90 degrees, the flow path varies from one port to another. That makes it useful for flow diversion applications.

T-port plug valve

- flow path in T PORT plug like T SHAPE. When the plug moves to different points, it can control 3 ports, make a connection with 2 ports, and restrict the 3rd, or control and block all ports.

- T-port plug valve used for mixing, diverting, and off-flow.

Plug valve vs. ball valve differences

| Feature | Plug valve | Ball valve |

| working | It plugs through an opening that regulates the flow in ports. | it is a hollow, perforated bal that manages control flow |

| Sealing features | It has a larger sealing area, good sealing features, and requires high torque | it is low weight, small sealing area, and low efficiency compared to plug valves |

| Types | Its types are based on lubrication and plug shape, and come in rounded and rectangular shapes | Its types are bore size and ball support features. |

| Maintenance | Easy | Difficult cleaning process since has deep-seated parts. |

| Cost | Less costly. | costly. |

| Application | used for abrasive materials such as sewage, mud, and slurries. | part of automation in industries such as natural gas, oil, LNG, and plumbing. |

| Longevity | low durability. | highly durable. |

Plug valve applications

The basic applications of a plug valve are as

- plug valve a part of gas processing plants since it can handle high-pressure and temperature conditions. It provides strong sealing that provides gas handling.

- plug valve handles different fluid features such as flammable, toxic, and thick fluids. It is good for the petroleum and chemical industries.

- Plug valves provide high speed and on/off for different fluids.

- Plug valves also control high flow rates and low resistance for flow and are good for liquid handling applications.

- Plug valves provide regular flow rates and also handle high-viscosity fluids since the valve has an easy flow path.

- Plug valves work well in high-temperature conditions and provide a seal for vacuum applications.

Selection factor for plug valve

There are some factors for the selection of a plug valve.

Fluid type

- lubricated plug valve is preferred for high temperature, pressure, and abrasive fluids

- • An A2 port plug valve suffices for on/off control. A3 port plug valve provides mixing and diversion functions.

- If lubrication does not work well, a non-lubricated plug valve works well.

- Make sure that the material of the valve has compatibility with the medium. such as a plastic-coated plug used for corrosive media.

- The size of the valve must be according to the piping dimension. End connection needed to support the pipeline for simple connection

Benefits of Using Plug Valves

Plug valves provide different advantages for easy operations.

- It has good sealing features and is completely off in closed conditions, reducing leakage and controlling fluid flow that is hazardous for the environment.

- Its working operation is simple since we can close or open the valve through rotation of a quarter turn. Its control is so fast that it makes it preferable where a fast response is needed.

- Its simple design: the plug does not make a 90-degree or 180-degree bend, so it helps fluid to move with less pressure on the valve. so preferred for high-flow applications and systems that work at high pressure for pushing larger fluid in pipes since energy saving is an important point

- Plug valves easily handle different media such as liquids, corrosive substances, and gases, and are preferred for different processes and installations.

- This valve is made with high-performance polymers that increase working life. It reduces wear and tear and easily manages different conditions for a longer working life.

- The main features of the plug valve are bidirectional flow, so fluid can follow any direction. With that, it provides easy installation, since flow occurs in both directions, so there is no need to consider a certain direction for moving fluid.

- Cast iron materials are used for making the plug valve, so the plug can be easily pulled out, and the valve uses fewer moving components, which requires low maintenance and reduces downtime. So this valve is a low-cost option.

- Plug valves can handle high temperature and pressure, so they work well in different conditions with a stable design.

Disadvantages

- It uses high force for high friction.

- Its larger size required an actuator since it did not work with the actuator.

- It has pressure losses due to the reduction of the port.

- Its cost is higher than a ball valve of the same size.

Read also