A car has many important parts; the serpentine belt is one of them. The serpentine belt is considered an important component. If not working well, it affects the driving process. This belt provides power to different engine parts. If it breaks or is not working well, the car stops moving, so proper maintenance is needed. In this post, we will cover the detailed features of serpentine belts and related features. So let’s get started.

WHAT IS A SERPENTINE BELT?

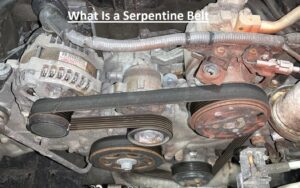

- Serpentine belt, also called a drive belt, is a continuous belt employed for operating different devices in the vehicle engine, like the power steering pump, water pump, alternator, AC compressor, etc.

- This belt operated through the idler pulley and the belt tensioner.

- For a belt moving more than 3 pulleys in a larger wrap angle, controlling slipping, idler pulleys opposite to the belt back are added, making the belt like a serpentine shape.

- A serpentine belt exists on the front engine block of the car. This belt has different ribs fitted over grooves with pulleys and engine parts.

- The strap delivers effective power from the crankshaft to components where power is needed. This belt also has features for minimizing vibrations and noise for accurate assembly of different engine-relevant parts.

Serpentine Belt Working Process

- The serpentine belt is operated with a crankshaft pulley configured on the engine. Here it is wrapped over different pulleys that deliver power to engine parts.

- Belt wound over the crankshaft pulley in a round shape

- This belt design minimizes wear and tear for delivering the same power to all parts. The serpentine belt uses an automatic tensioner for handling tension variations when the load increases on the engine.

- The tensioner makes sure all components get constant power that maintains vehicle performance.

- If the serpentine belt is damaged or not working well, it faces different faults: a worn or dry serpentine belt, improper pulley configurations, cold weather, and improper connections cause a misaligned belt.

Serpentine Belt Importance

- In older vehicle vehicleversions engine uses a V-belt structure rather than a serpentine belt. A belt of any type causes the movement of one or two parts. Belts also maintain the accurate working of the car and engine.

- Serpentine belts are used as a replacement for thin belts and control different parts.

- It is made with quality rubber and provides strength for power transfer to other pulleys.

- The serpentine belt also works as a single module that uses different V-belt systems and gives high belt tension without any stretching.

- One serpentine belt uses less engine space compared to many other belts. Its replacement is easy and avoids the flipping that occurs for thin V-belts.

Serpentine Belt Vs. Timing Belt

These two belts drive different parts of vehicles, like water pumps, alternators, power steering pumps, and AC compressors.

serpentine belt: a single belt configuration that winds over different pulleys and parts of engines to provide high power with small size and weight.

It is effective and uses low energy. The serpentine belt is a reliable and effective belt for advanced engine types.

The timing belt is a two-piece belt made with teeth. It is part of an older version of engines and has low efficiency compared to a serpentine belt.

A timing belt has higher efficiency than a serpentine belt since synchronization to the crankshaft causes valves to open and close at the same time.

The serpentine belt is an effective option in new engine types since the timing belt’s complex design and difficult maintenance are not part of newer cars.

Bad Serpentine Belt symptoms

There are many signs of a faulty serpentine belt that must be considered for the accurate working of belts.

Noise

- Noise generated in the engine means you have a serpentine belt. When you find a high-pitched sound, check the belt. Since a damaged belt causes noise, a loose belt also causes noise. So when finding these early signals, solve faults before they become serious.

Dashboard warning signs

- The alternator of the vehicle charges the car battery and also provides power to the serpentine belt. If the alternator is not working well, it causes faults of serpentine belts. The

- Dashboard lights will glow when the vehicle battery is running down. When the battery light is on, it means the car battery does not work well.

Difficult Steering

- The power steering system also operates well through the serpentine belt. If power steering is not working well, maneuvers become difficult.

- So it needed high pressure for movement. So power steering loss is a sign of serpentine belt faults. but improper power steering fluid also needed to be inspected for the difficult steering process

Serpentine belt damaged

- inspect serpentine belt If you find any damaged main belts, they will not work well. Some other sign of cracks, separation, and abrasions shows a damaged belt.

Air conditioning not operating

- The AC system of the car gets power from the serpentine belt. If the belt is not working, it means cold air from the vents is not being received.

- So a problem with the AC occurs, since the sincecompressor getting power from the belt. So check the belt for finding further faults.

Overheating

- The water pump gets power through the serpentine belt also. That part reduces engine temperature.

- A damaged belt not operating the pump causes engine overheating and any other faults that occur. Engine overheating also occurs due to a blown head gasket that makes costly repairs.

car, sudden stops while driving

- if the alternator is not getting power from the serpentine belt. The car stops working when battery power is running short.

- For restarting, no power exists. so it’s best to solve any sign before getting serious damage.

How To Inspect a Serpentine Belt

Follow these steps for inspection of a faulty serpentine belt.

Visual Inspection

- Perform a visual inspection for checking that oil, coolant, and power steering fluid leaks occurring on the belt affect the belt rubber. so it can easily stretch and be damaged. So when you find any faults in belts, change them.

Check Belt Tension

- With the help of a tension gauge, check accurate tension. The belt turns about 90 degrees for the loose point. The belt comes with an erroneous automatic tension, affecting the misaligned tensioner. If the belt does not adjust to the accurate tension level through the manual tensioner, use a new belt.

belt tension inspection

- Belt inspection tool used for belt inspection.

When Serpentine Belt replcement needed

When any faults occur, replace the damaged belt. Inspection of the serpentine belt occurs during oil replacement. When found damaged during inspection, replace the belt with a new one.

How to Replace a Serpentine Belt

Follow these points for the replacement of a serpentine belt.

- First, find the location of the belt tensioner and use the belt tensioner tool over the tension bolt.

- For making the bolt loosen, perform pressing and pulling of the tensioner in the proper direction.

- Disconnect the belt, and put on a new belt.

- Then remove tension for accurate positioning of the belt on pulleys.

Some Serpentine Belt Replacement Tips

- Check that the belt routing is set; set the belt on a small pulley.

- Remove the front wheel to make easy access to the belt. that helps for belt routing and accurate positioning of the crankshaft pulley

- solve fluid leaking

Serpentine Belt Advantages

- It is more effective than other belt systems and uses little space in the engine.

- By using a larger belt than many, belts apply high tension without stretching.

- High tension affects slip, which increases belt working life since it provides high mechanical strength.

- Low slip helps to use a low-ratio pulley that minimizes the workload on the engine with high fuel efficiency.

Disadvantages

- The main limitation of a single belt is that if damaged, it affects complete system operations.

- The working of the water pump, power steering pump, and alternator stops.

- The vehicle loses engine cooling with that belt before getting indications to solve or replace the error.

- If any component, like the power steering pump, not working affects the complete system.

How long do serpentine belts last?

- Usually, the working life of serpentine belts is in the range of 50,000 and 100,000 miles, according to vehicle driving conditions and types.

- Regular inspection of the belt helps it to work longer before developing any serious faults.

- Regularly check oil and brake pads.

What Happens if I Don’t Replace the Serpentine Belt?

- If you find any sign and ignore it and do not replace it, it can damage the vehicle. Due to a bad serpentine belt, the driver faces failure of different parts of the vehicle, like the alternator, water pump, and air AC system.

FAQs

How does serpentine work?

- serpentine belt employs pulleys and a belt and belt tensioner for power transfer from the engine crankshaft to other parts. serpentine belt used in modern cars, and it moves during the car’s running state

Can a car run without a serpentine belt?

-

- Yes, but for a short time if the battery has some amount of charge and the water pump is operating on a separate drive.

- Driving without a serpentine belt is not safe, and it causes other systems to get damaged.